It was a very difficult and exhausting job to cut tile, stone before. Earlier it was strictly a manual work where people uses to craft the tiles themselves by using their hands and basic tools into desired size and shape. This process was slow and laborious. However, with the new technology we have something known as waterjet cutting by Baotao Machinery which revolutionized the way we used to do tiles and stones cuts.

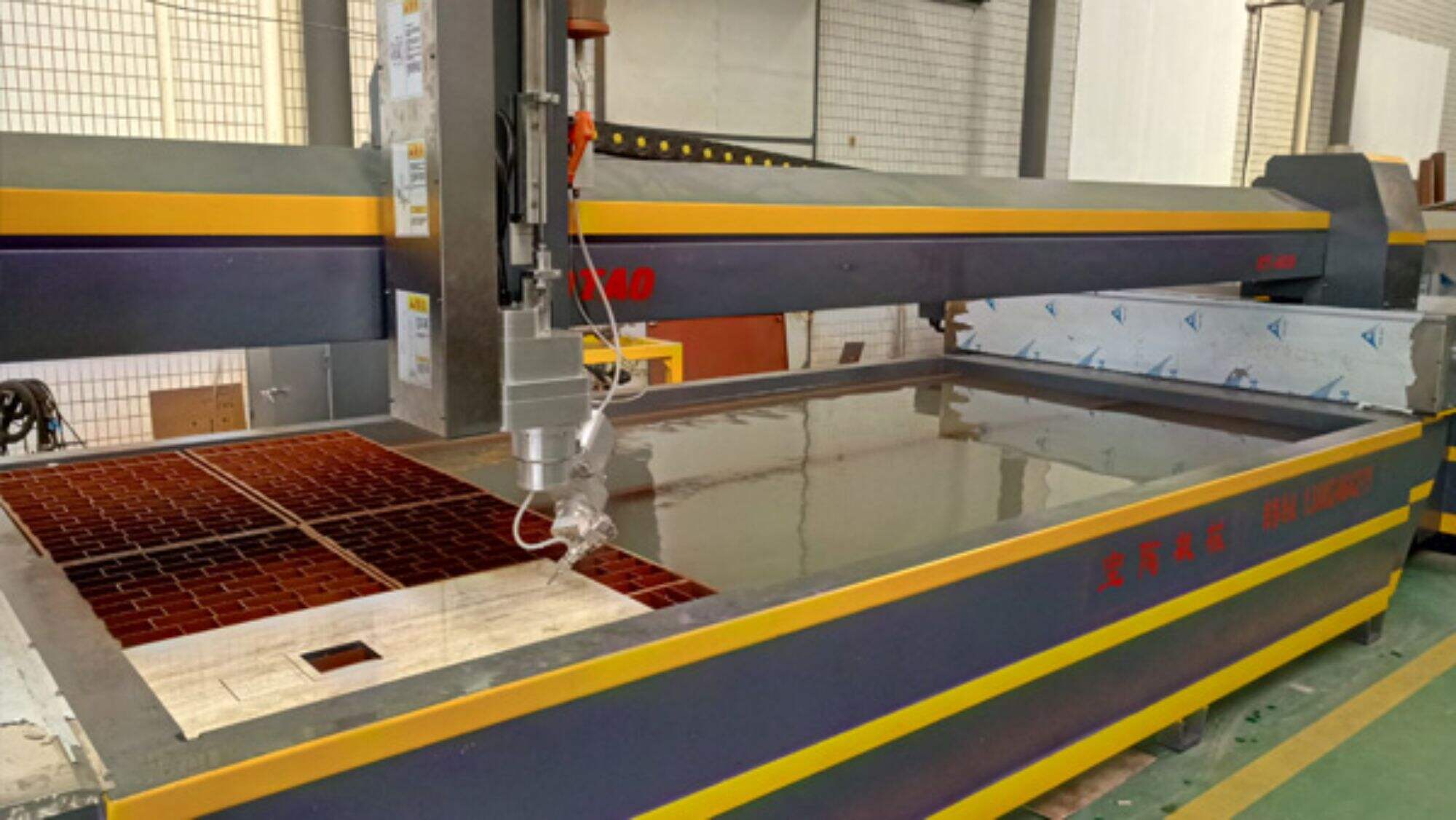

Waterjet cutting method is a special technique in which high-speed, thin stream of water mixed with small bits called abrasive particles. That jet of water is extremely powerful enough to bore through many materials with ease. Due to this technology, tiles and stones can be cut with much greater ease, quicker and accurate cuts than ever before.

The Perfect Cuts from Waterjet Technology

Most of the companies which make tiles and stones love to use waterjet technique because it helps them cutting material with perfect accuracy. Therefore, water jet cutting machine allows manufacturers to achieve different shapes in tiles or stones. They also know how to carve on the tiles or stones.

Waterjet cutting also allows manufacturers to deliver designs in ways that had never been feasible. This led to the tiles and stones looking more unique as well, thus making for a much wider range of designs. This allows creation of many new ideas to design tiles and stones for being artistic or temple.

Creating Original Designs Using Water Jet Cutting

Waterjet cutting can achieve far more than straight line incisions. This can also be used to make beautiful and complex tiles, stones etc. This program is combined with the machines where actually waterjets cut and so designers can produce countless designs which are in their imagination. So, they are able to make curves which means you can have zero parts with sharp corners and more of a smooth rounded edge.

Their ability to produce intricate and fine designs along with edges that are just picture perfect really make a difference for them in helping overhaul the tile stone industry. This allows designers to flex their creativity like never before. This technology has opened up the doors to an endless array of new and exciting tile and stone products.

Cutting with waterjet systems is eco-friendly

It is necessary in the present day, with environmental concerns taking top priority for many industries like tile and stone manufacturing. Waterjet cuts are not just accurate but also eco-friendly and no wastage is created using this cutting technology.

Older cutting methods generated dangerous dusts or produced toxic materials, whereas there is no such byproduct from waterjet cutter. The cutting is accomplished with a gentle flowing waterjet, and the only waste created from this process are small pieces of an abrasive material that can be collected and reused. This is one of the most significant benefits in terms of water savings compared to traditional cutting that can contain a large amount o water waste.

What Makes waterjet cutting so popular on this day?

There is a great need for a product that can be quality made, efficiently and environmentally produced for the tile and stone industry. For this reason, waterjet technology is an excellent option that meets all these requirements.

In fact, waterjet cutting has completely revolutionized the industry as we know it, allowing for tiles and stones to be cut with more speed precision than ever. These machines are also used with certain computer programs that enable endless creative tile, stone and all other applications and ease the process of looking beautiful than real-made work.

Furthermore, when we used this technology for our tiles and stone production then it is a Green Process so help to save the wastage of Ecology. And they are right to choose it, will tell you why, waterjet cutting with some significant advantages over any other option.

Conclusion

Waterjet Technology has revolutionized our way of cutting tiles and stones. It has improved the process by providing a more accurate, faster and environmentally friendly solution. With the recent advances in cnc water jet cutting machine technology, we can develop some of the best shapes and designs with our specialize tiles cuts which would be very difficult for anyone in traditional way to make. The invention of water jet cutting has forced tile and stone manufacturers to adapt in order to keep up with the needs of a 21st century design aesthetic that prizes sustainability.

EN

EN

AR

AR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID UK

UK VI

VI TH

TH TR

TR BE

BE KK

KK TG

TG UZ

UZ