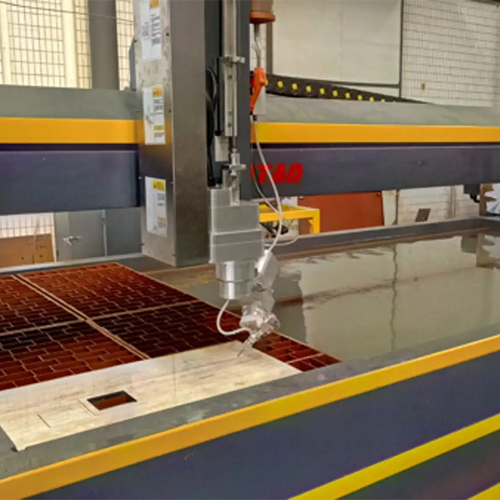

A CNC water jet cutter, an indispensable part of manufacturing is one tool that ideally need to acquire due it precision and gentle nature (it does not heat up other materaials like some cutting system). Choosing the bestCNC water jet cutter factoryFrom there, it should be obvious how a good CNC water jet cutting machine manufacturer can drastically improve your outcome across multiple dimensions - quality of output, production efficiency and overall business operation/market expansion. In this guide we will take you by the hand to quickly review key aspects that should be given importance when picking a top manufacturer, tips on how to identify trustworthy suppliers, examples of some great manufacturers in business and few helpful pieces of advice about looking for CNC water jet cutter factory.

Qualities of a Manufacturer Producing the Best CNC Making Water Jet Cutter

On the part of quality manufacturers one major thing that definitely be considered is there sourcing and use of latest technology in their CNC water jet systems. That requires high-pressure pumps, minute motion controls and advanced control systems in order to hold close tolerances from part after the next. You even have to receive machines that can use differing materials, should they are tailored to fulfill the demands of your application and this is quite another area where a high-quality manufacturer would guide you. You should check that the factory operates under a strict quality assurance process and can supply you with full after-sale technical support, in order to maximize production time life of your investment. Watch customer reviews, and case studies from these manufacturers know how one manufacturer differs than the other based on real word experience.

Quality And Efficiency - The Ultimate Guide

An efficient purchase of a CNC water jet cutter requires attention to quality. Both the reliability and power of these pumps, as well as their effect on the nozzle jetstream shape (which determines how fast sections can cut), play a role in cutting speed. Yes, the programming software built in these machines provides an opportunity to use machining effectively by saving material; however ask for its capability on other fronts as well. If you don't believe, the best way to know if a machine is performant or not by seeing it operates in real life face-to-face or doing so via an operation video.

Scroll CNC Water Jet Cutting- Where to look the best supplier

Step 1: Build a Reputation Matrix of all the manufacturer Attend some trade shows around the world and get to know suppliers in person, or hear from vendors exactly with a number you can compare costs and ROI When possible, set up an on-site visit at the factory so that they assess their production flow and working environment.

Lacoste A&F Kirkland Guess Lee Boss Gass Premier Profiles

While we obviously need to keep our customer details confidential and as such cannot name them, these characteristics of long-term experience are often typified in many of the leading CNC aluminium water jet cuttingtop-level plants. worldwide customer base solid R&D explanation of what they continued to deliver online

One of the best ways to find a reliable CNC water jet cutter factory is through different resources.

I knew a lot of people in the manufacturing industry so I battled through BabeThread.

Study: Use your industry news resources and online CNC machinery forums.

Perform a Pilot Project / Test Run : Consider setting up a pilot project or test run on the machine you are considering.

Lifestyle||Perform a financial health check: Check the manufacturers current position

Training Opportunities - Evaluate the manufacturing company training programs for team reinforcement

Lastly in figuring out the best CNC water jet cutter producer, also focus on with regard to technical capabilties and manufacturer support/reputation. This guide is designed to help you make sound decisions that will be a credit to your manufacturer and paying dividends down the line, if respect for those steps as well their underlying notions.

Table of Contents

- Quality And Efficiency - The Ultimate Guide

- Scroll CNC Water Jet Cutting- Where to look the best supplier

- Lacoste A&F Kirkland Guess Lee Boss Gass Premier Profiles

- Study: Use your industry news resources and online CNC machinery forums.

- Lifestyle||Perform a financial health check: Check the manufacturers current position

EN

EN

AR

AR FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID UK

UK VI

VI TH

TH TR

TR BE

BE KK

KK TG

TG UZ

UZ