Кай бори охир шумо табақ ё косаи дӯстдоштаи худро гирифта, он кунҷҳои комилан ҳамвор ва ҷилодорро тафтиш кардаед? Ин як мошини сайқалдиҳии канори сафолист, ки ин ҷодугарӣ мекунад - ва бо дидани видео, шумо аллакай медонед, ки чаро он кор мекунад. Ин чизели барқӣ аст, ки махсус барои гирифтани кори санъати сафолии шумо аз бозии сифр ба сатҳи касбӣ сохта шудааст.

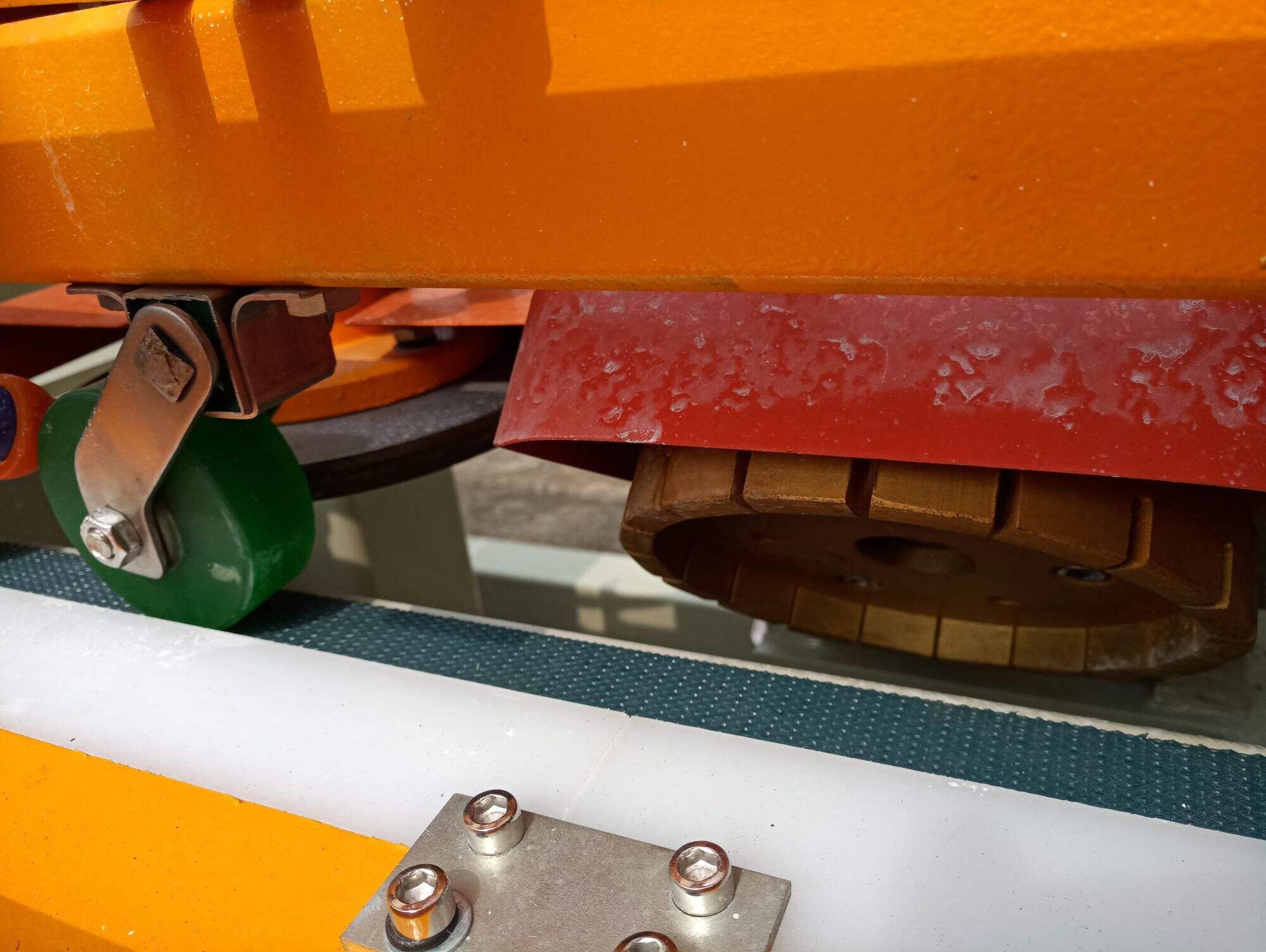

Мошини сайқалдиҳии канори сафолӣ роҳи ниҳоии ноил шудан ба камолот дар робита ба давомнокии умри кунҷҳо мебошад. Ин мошин канори гармоникии ашёҳои сафолиро бо асбоби махсуси тозакунандаи чанги зериобӣ бодиққат суфта ва сайқал медиҳад, ҳама қисмҳои ноҳамвор ё нобаробарро ислоҳ мекунад, то натиҷаи ниҳоии якхела ва покизаро ба вуҷуд орад. Он объектро пойдортар мекунад ва ба микросхемаҳо ё тарқишҳо камтар майл мекунад ва инчунин имкон медиҳад, ки он ба таври визуалӣ беҳтар ба назар расад.

Мошинҳои сайқалдиҳии канори керамикиро ин қадар беназир мегардонад, ки онҳо ҳангоми поляк ба шумо дақиқ ва баланд медиҳанд Ин мошинҳоест, ки бо истифода аз сенсорҳо ва асбобҳои ченкунӣ барои сайқал додани дақиқтарин кунҷҳо, ки мувофиқи стандартҳои пешакӣ муайяншуда пайдо мешаванд, кор мекунанд. Дар соҳаҳое, ки кори дурусти ашёи сафолӣ ҳаётан муҳим аст, масалан дар дастгоҳҳои фрезерӣ ва муҳаррикҳои реактивӣ, хатогиҳои хурд метавонанд оқибатҳои калон дошта бошанд.

Пайвастагӣ яке аз натиҷаҳое мебошад, ки технологияи сафолӣ ба даст овардааст. Маҳз аз ҳамин сабаб аст, ки ҳама ашёе, ки бо истифода аз мошини сайқалдиҳандаи мо коркард карда мешаванд, новобаста аз андоза ва шакли онҳо, метавонанд ба таври равшан сайқал дода шаванд. Ин якрангӣ барои соҳаҳои истеҳсоли оммавии зарфҳои сафолӣ, аз ҷумла зарфҳои хӯрокворӣ, зарфҳои санитарӣ ва сафолии саноатӣ комилан муҳим аст.

Мошини сайқалдиҳии канори сафолӣ бо бениҳоят универсалӣ маълум аст, зеро он метавонад қариб дар ҳар як намуди ашёи сафолӣ, ки дар аввал бо ҳамон сатҳи ҳамвор канори он хоҳанд буд, анҷом диҳад. Барои коркарди як қатор масолеҳи сафолӣ тарҳрезӣ шудааст, ки аз сафолии нозук то сафоли саноати вазнинро фаро мегирад. Илова бар ин, шумо метавонед онҳоро тарҳрезӣ кунед, то ороишоти сершумори канориро эҷод кунед, ки аз як марра ҳамвор ва сайқалёфта то намуди зоҳирии беназири бофташуда барои ҳама ҳассосият ҷолибанд.

Бартарии муҳимтарини истифодаи мошини сайқалдиҳии канори сафолӣ ин вақт ва хароҷотест, ки шумо метавонед аз анҷомдиҳии мунтазам сарфа кунед. Равандҳо, аз қабили сайқал додани дастӣ ё пармакунӣ метавонанд меҳнатталаб ва суст бошанд, дар ҳоле ки мошини сайқалдиҳии канори сафолӣ равандро суръат мебахшад, ки ҳалли муассир ва камхарҷро таъмин мекунад.

Агар шумо хоҳед, ки қисмҳои сафолии худро комил анҷом диҳед, ин аст, ки беҳтарин роҳи ба даст овардани ин натиҷа бо мошини сайқалдиҳии канори махсус дар сафол тарҳрезӣ мешавад. Он асбобҳои сайқалдиҳиро истифода мебарад ва ба он равона шудааст, ки кунҷҳои мошин ҳамвор ва инъикоскунанда дошта бошанд, ки табиатан дар навбати худ "эффекти визуалии ҳайратангезеро таъмин мекунад, ки бешубҳа таваҷҷӯҳи бинандагонро ҷалб мекунад".

Баотао мошини сайқал додани канори сафолии RD маркази зиёда аз 6,000 метри мураббаъро паҳн кард. Он як таъминкунандаи таҷҳизоти буридани сафолҳо ва инчунин таҷҳизоти сангбурӣ мебошад. Он дорои патентҳои сершумори маҳсулоти сифат мебошад.

имкониятҳои тиҷоратӣ мошини сайқал додани канори сафолӣ дар кишварҳои сершумори ҷаҳон, мо ба мизоҷон хидматрасониро дар 200 кишвари ҷаҳон пешниҳод менамоем. Илова бар ин, ширкат муносибатҳои ҳамкорӣ барқарор кард, ки провайдерҳои сершумори хидматрасонии логистикӣ амнияти логистикиро ҳар як интиқол таъмин мекунанд.

ширкат аз сертификатсияи ИА ИА гузашт, занҷири пурраи таъминоти истеҳсолӣ: таҳияи тарҳрезӣ инчунин истеҳсолот (сохтакорӣ, мошини сайқалдиҳии канори сафолӣ, васлкунӣ) Мошини санҷишӣ, хидматрасонии пас аз фурӯш ва ғайра фармоиш медиҳад. дастаи ҳамаҷониба. кафолати хидматрасонии дастрас ба мизоҷон.

ширкати тиҷоратӣ пеш аз ҳама таҷҳизоти коркарди амиқи санги плитка, инчунин технологияро истеҳсол мекунад. дастаи тарроҳии ботаҷриба ба мизоҷон ҳалли талабро пешниҳод мекунад. шакл, мошини сайқалдиҳии канори сафолӣ, мошини истгоҳи коркард фардӣ карда шудааст.