Viable Marketing Article

Revolutionizing Marble Cutting: Find The Benefits of CNC Devices

Do you want producing gorgeous and marble and its own durable, such as for instance flooring, wall space, countertops, sculptures, or designs? Do you wish to improve your effectiveness, accuracy, and usefulness in cutting marble, without cutting your quality and its large or? If that's the case, you might want to consider using a CNC marble product cutting and its own a convinced and its forward trustworthy unit which can help you release your creativity and production. Baotao Machinery cnc granite cutting machine are going to make clear just what a marble and its CNC cutting, the reason why it really is beneficial, utilizing it precisely, and finding top-notch products and solutions.

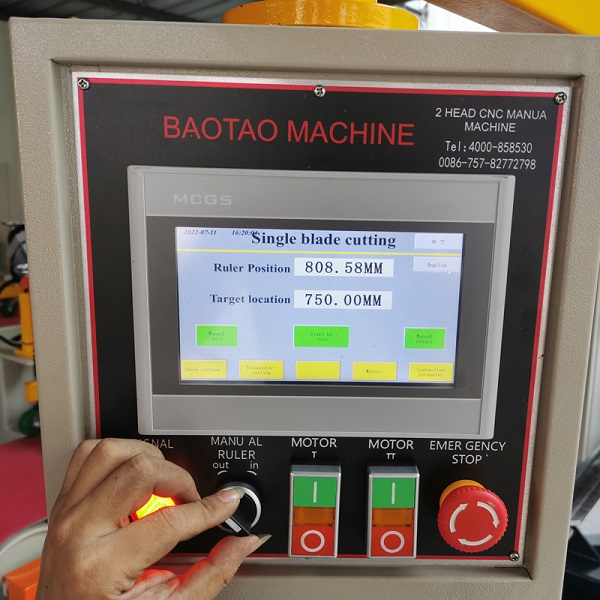

A CNC marble device cutting a form of saw that makes usage of computer control numericalCNC) technology to automate and enhance the cutting procedure of marble pieces or obstructs. The Baotao Machinery cnc marble cutting machine apparatus features a framework durable helps a cutting mind or spindle, that'll be running on an electric engine driven laden with a diamond knife or just about any other cutting tools. The cutting head can horizontally move vertically or along different axes, such as for instance X, Y, and Z, in line with the directions which are electric programs which are inputted in to the product's operator getting a applications. The programs is custom made to suit the proportions being forms that are specific sides, sides, habits, or designs you want to create, based on your design or design.

A CNC marble product cutting several benefits over standard or cutting and its manual, just like the after:

- Precision: CNC products decrease marble a lot more precisely and regularly than individual arms, as they are less prone to mistakes or variations brought on by weakness, ability, or aspects and that can be ecological. And that means you have the ability to achieve the same or better quality of cutting results with less waste, rework, or time.

- Effectiveness: CNC devices can cut marble quicker and much more efficiently than manual techniques, as they can work continuously and instantly without pauses or interruptions. This means you'll be able to produce more marble items in less time reason why is enough reduced work costs, which could boost competitors and earnings.

- Flexibility: CNC machines can lessen marble in several means and guidelines, with regards to the programs that you input or select. Which means that it really is easy to change or duplicate your patterns that are cutting necessary that you can develop diverse and complex types or forms that might be difficult or impossible to attain by manual practices, and.

- Protection: CNC devices have actually integrated security functions that can stay away from accidents or injuries, such automatic shut-offs, alarms, or crisis stops. Which means you can comply with the security demands and regulations of the industry the device might be run by you with less threat of harm to your self or your workers, and.

- Development: Baotao Machinery CNC marble tile cutter can launch your imagination and innovation in marble cutting, as you can test out brand name ideas being brand new designs, and impacts that may split up your products from other individuals. Which means it is possible to build your brand, reputation, and client base by providing unique and marble customized that get together utilizing the needs and preferences of one's market.

Although Baotao Machinery cnc water jet cutter are usually safe to work with, they nonetheless need correct education, upkeep, and path in order to avoid accidents or issues. Below are a suggestions which can be few will allow you to run a CNC marble device cutting:

- See the manual and its specific extremely very carefully proceed with the instructions.

- Wear correct equipment private its protectivePPE), such gloves, goggles, earmuffs, or aprons.

- Pull any free, razor-sharp, or items which are combustible the product as well as its surroundings.

- Check out the product's power supply and environment force before beginning the cutting process.

- Pick the diamond and its particular correct or cutting tool when it comes to task particular.

- Input the programs which can be variables which are proper these devices's operator.

- Take notice of the cutting procedure and monitor the apparatus's overall performance and condition.

- Alert the various various other employees or clients nearby once the unit is cutting.

- Stop the equipment right away if you observe any noise which is irregular vibration, or behavior.

- Turn the machine off and disconnect the power source once the cutting procedure is completed.

cnc marble cutting machine scope expanded multiple countries around globe, providing services clients more 200 nations around world, company established cooperative relationships various logistics service providers order ensure safety logistics each shipment.

company been cnc marble cutting machine EU CE certification has complete supply chain production includes development design (forging welding, welding assembly) testing equipment, after-sales services, etc. guarantees quality machine when arrives source. complete team provides assurance service customers.

principal business firm manufacturing deep processing technology equipment tile stone. experienced design team offer customers solutions they seek. form, color, logo, processing station machine equipment cnc marble cutting machine.

Baotao manufacturing RD centre covers area more 6,000 square meters. offers tile cutting machines stone cutting machines. cnc marble cutting machine several patents its quality product assured.