What is a Stone Polishing Machine?

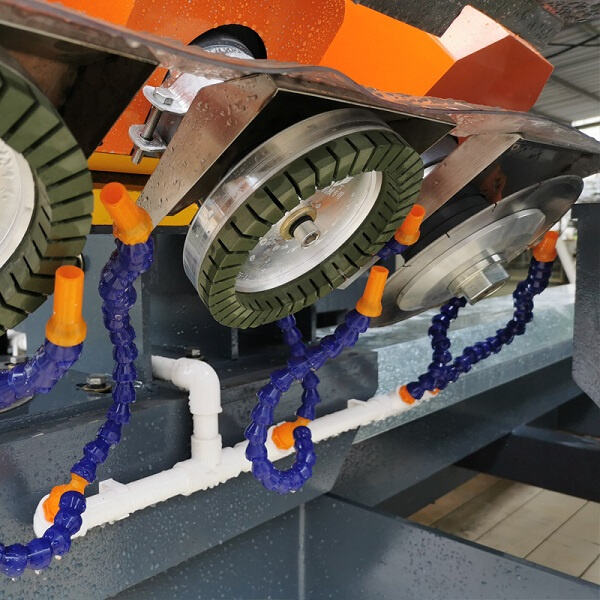

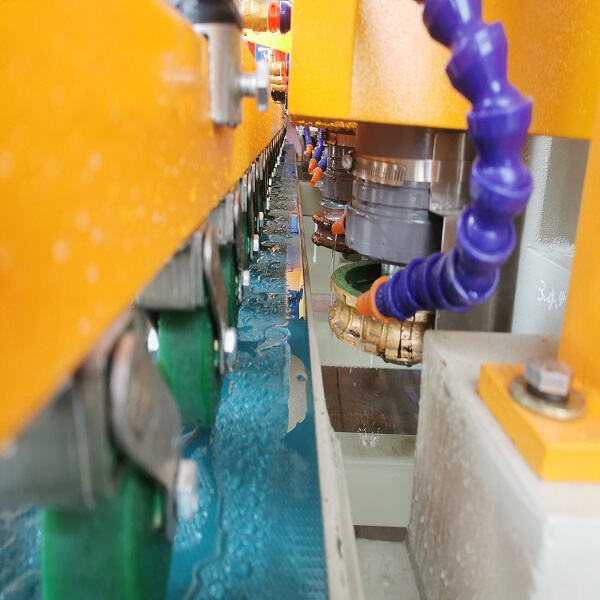

A stone polishing machine is just a machine used to polish stones or any certain stone-like area. It is built with a rotating head abrasive pad that work in conjunction with water and polishing substances to supply a smooth and shiny finish towards the rock. Baotao Machinery granite stone cutting machine is utilized in the construction and renovation industry to polish granite marble concrete, and other stone areas.

There are many advantages to presenting a stone polishing machine. Probably the most benefits significant its capacity to save yourself money and time. Utilizing a stone polishing machine is an easy economical method of large regions of rock areas quickly. Additionally decreases the need for handbook labor, which could bring about a safer and more efficient workplace. Another significant benefit its power to achieve a top-notch finish. Baotao Machinery cnc marble cutting machine are created to produce consistent and consistent results, allowing for an expert finish time. The use of polishing and water compounds also reduces the alternative of damaging the stone surface, ensuring it continues to be smooth and scratch-free.

The stone polishing machine has undergone significant innovation many years. From the initial design has seen improvements in power, rate, and effectiveness. Advances in technology have led to the growth of multifunctional devices that could perform tasks being different such as grinding and polishing. One innovation available on the stone market polishing machine the use of diamond pads. These Baotao Machinery automatic chamfering machine are created to last longer produce a better finish, making them a well-known selection for professional stone polishing tasks.

Safety is an aspect necessity of a stone polishing machine. Operators must wear appropriate individual protective equipment, such as gloves, goggles, and ear security. The use of water can result in an also slippery work, enhancing the chance for slips and falls. It is necessary to make sure the ongoing workshop is clear of dangers and kept clean to cut the risk back of accidents. Proper use regarding the Baotao Machinery cnc granite cutting machine is also critical. The operator should make sure the stone surface is clean and free from debris before use. They need to additionally find the appropriate abrasive pads polishing compounds for the rock being polished. The machine is operated at a slow rate and increased as required to prevent damaging the rock area.

When buying a stone polishing machine, it is very important to consider the standard of the item and the ongoing service supplied. High-quality machines are more durable and efficient, enabling a far more reliable and lasting investment. Good client service can be essential also. A reputable Baotao Machinery granite edge polishing machine supply tech support team, training, and after-sales service so that the machine will continue to execute at its best. They can additionally assist with troubleshooting and maintenance, reducing downtime and increasing efficiency.

operations grown over 200 countries, we provide solutions clients these countries. company established relationships variety logistics service providers, making sure stone polishing machine every shipment.

Baotao manufacturing RD stone polishing machine covers area 6,600 square meters. offers tile cutting machines stone cutting machines. It a variety patents product quality guaranteed.

company passed EU CE certification, complete stone polishing machine chain includes development design, production (forging welding, forging) Test machine, after-sales services after-sales service, etc. ensures high-quality equipment manufacturer full team also provides customers Guaranteed Service.

business company primarily manufacture tile stone deep processing equipment well as technology. skilled design team offer customers solutions require. shape, color stone polishing machine, processing station machine personalized.